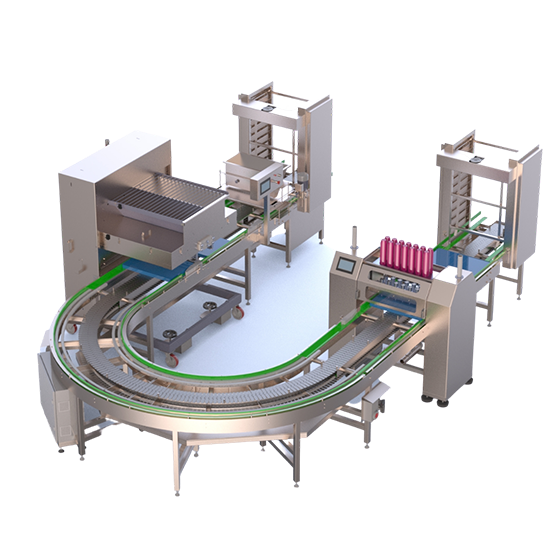

For cooking in tunnel oven and closed tray circuit. Conceived as modular lines configurable according to the desired variety of products.

Dosing, injection or decoration heads are placed and removed on the line, which gives it the necessary flexibility to take advantage of the same multiproduct production line.

Easily expandable to future formats. Possibility of adding a cooling tower in trays or at the outlet of the “Rocker Tower” or “Spiral” type demoulding. “

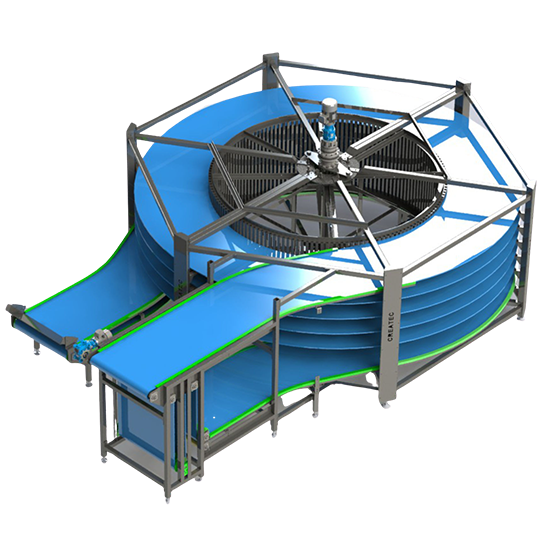

Designed for cooking in rack ovens. With automatic loading and unloading of trolley.

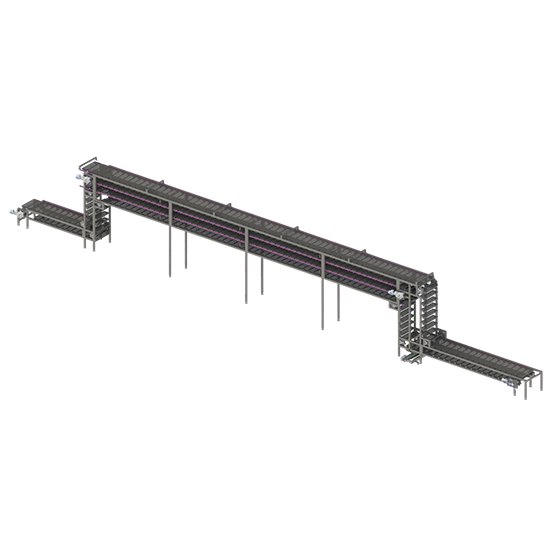

Transportador bandejas en forma de “U” o recto.

Attachable cream injection heads, demoulding robot, deposited paper or mold release head, dosing and decoration.

Multiformat and versatility in the minimum space. Product cooling in the trolleys themselves or it is also possible to add a cooling zone at the outlet of the “Rocker Tower” or “Spiral” type demoulding. “

Bienvenida/o a la información básica sobre las cookies de la página web responsabilidad de la entidad:

CREATEC ROBOTIC AUTOMATION S.L

Una cookie o galleta informática es un pequeño archivo de información que se guarda en tu ordenador, “smartphone” o tableta cada vez que visitas nuestra página web. Algunas cookies son nuestras y otras pertenecen a empresas externas que prestan servicios para nuestra página web.

Las cookies pueden ser de varios tipos: las cookies técnicas son necesarias para que nuestra página web pueda funcionar, no necesitan de tu autorización y son las únicas que tenemos activadas por defecto. Por tanto, son las únicas cookies que estarán activas si solo pulsas el botón ACEPTAR.

El resto de cookies sirven para mejorar nuestra página, para personalizarla en base a tus preferencias, o para poder mostrarte publicidad ajustada a tus búsquedas, gustos e intereses personales. Todas ellas las tenemos desactivadas por defecto, pero puedes activarlas en nuestro apartado CONFIGURACIÓN DE COOKIES: toma el control y disfruta de una navegación personalizada en nuestra página, con un paso tan sencillo y rápido como la marcación de las casillas que tú quieras.

Si quieres más información, consulta la POLÍTICA DE COOKIES de nuestra página web.